Washover Assembly

Things don’t always go as planned !! In drilling operations, pipes can get stuck and or borehole may contain debris or even lost tools. A Washover operation is performed to recover / clear or was the top of the fish and then proceed with fishing operation to remove the fish.

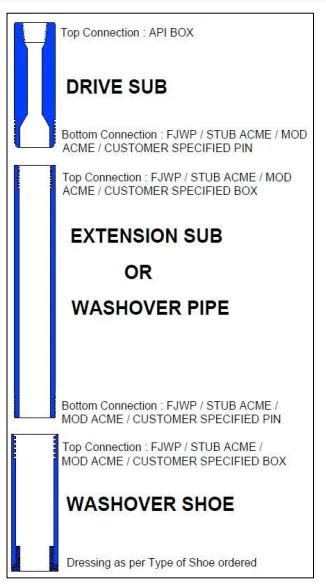

The Washover Assembly consists of ;

- 1. Drive Sub or Top Sub :

The Top Box API connection is connected to the drill string and the Bottom Pin (FJWP / Stub Acme / MOD Acme / etc) is connected to the Extension Sub / Washover Pipe.

- 2. Extension Sub :

It is a hollow tube with Top Box connected to the Drive Sub and Bottom Pin connected to the Washover Shoe. The length of the Sub is machined as per requirement.

- 2A. Washover Pipe :

It is a hollow tube with Top Box connected to the Drive Sub and Bottom Pin connected to the Washover Shoe. The length of the shoe (Range 1, Range 2 or Range 3) is supplied as per requirement. Either Extension Sub or Washover Pipe is used in the assembly.

- 3. Washover Shoe or Milling Shoe :

It is the bottom-most component of the assembly and used to washover the component to be fished out of the hole. There are various types of Mill Shoe s and dressed / hardfaced as per items to be milled

We can manufacture all washover items as per customer specific requirements.