EV - 6 Mud Lubricated Drilling Motors

Technical Summary:

The Element EV-6 Mud Lube Motor and components were developed from 20 ongoing years of

development of evolving motor designs, and most importantly by discussing with our

customers on what the demands, challenges and future holds to ensure performance,

operating costs and dependability are all met to provide the leading motor in the

industry.

The result is the Element EV-6. A brand new design that has taken the best of everything

Element has to offer, and amped up to exceed other product lines in every category in

every segment of a drilling motor.

Without adopting new components into an older design for a short term gain, the EV-6

provides all the requirements to perform in the most demanding wells and with the

strongest power sections available, while lowering operator cost per hour.

The EV-6 was also designed with service in mind. Assembly and disassembly procedures are

simplistic and uncomplicated, and provide the technicians areas for clamping, installing

and QC referencing making the motors time and cost efficient for turnarounds.

Features :

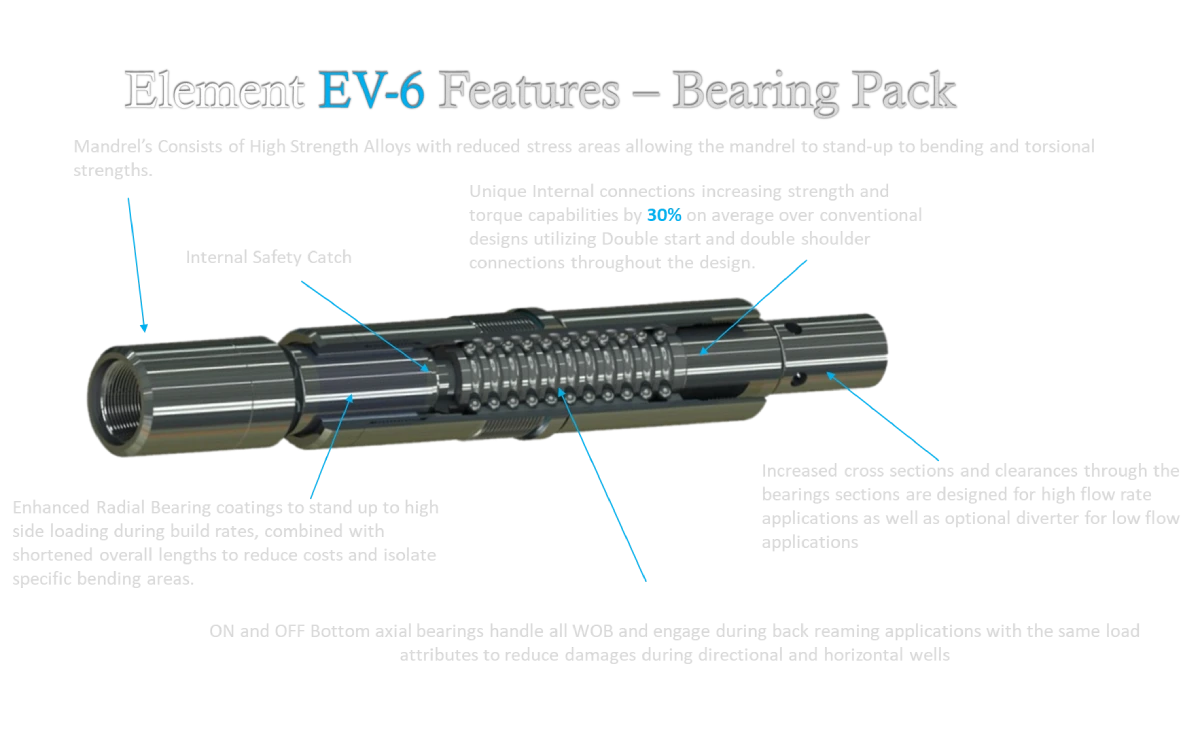

- Internal components feature Double Shoulder and Double Start connections, reducing thread wear while providing unmatched make up torques and yield strengths.

- Mandrels feature stress relief areas minimizing bending stresses which lead to material fatigue and possible failures.

- External Connections and tool body sizes allow for increased torque values, while providing maximum internal component strengths.

- Advanced Radial and Axial Bearings provided.

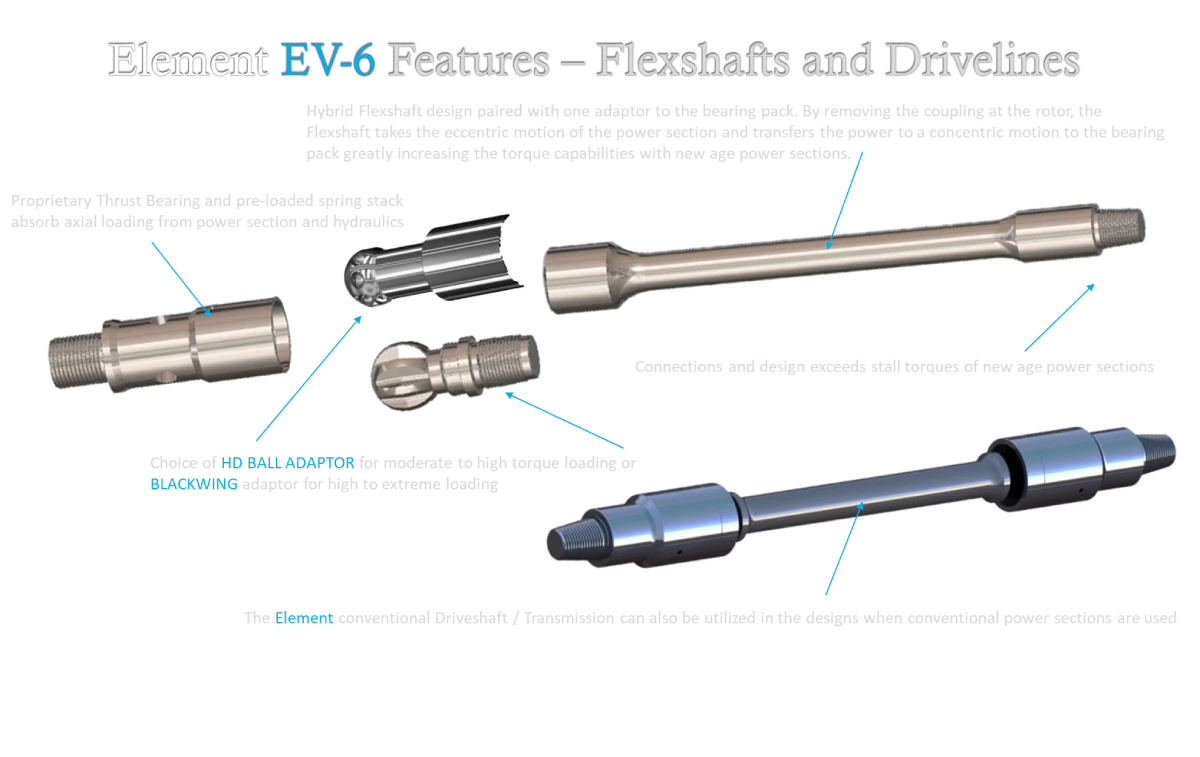

- Hybrid Flex Shafts provide torsional strength to handle all power sections and can be configured to meet specific customer connections and lengths.

- Proprietary thrust bearing and preloaded spring stack incorporated in the Flexshaft assemblies absorb high axial loads.

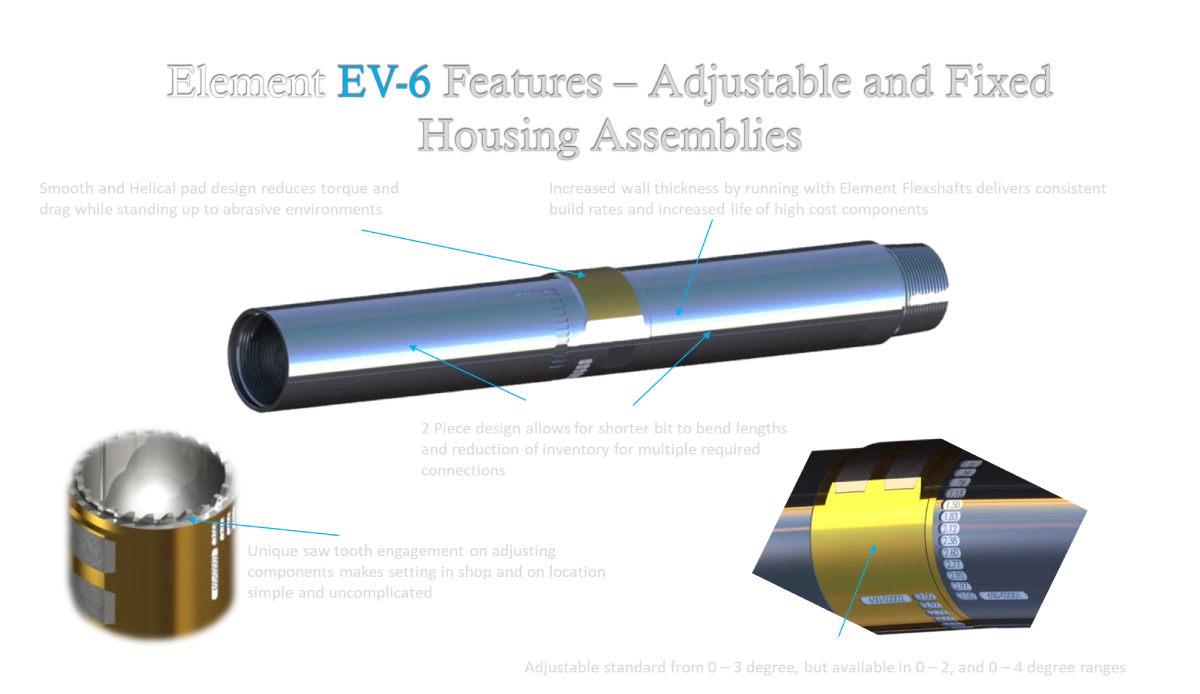

- Fixed and Adjustable housings feature large wall thickness to ensure consistent build rates and reduction in fatigue failure due to bending stress in large bore designs.

- Bit to bend lengths for Fixed and Adjustable Assemblies allow for constant and increased build rates with lower settings allowing for more control of well path through rotating and sliding the drill string.

- Internal flow areas designed to incorporate high flow rates

- Catch areas throughout the design allows for retrieval of the motor if a failure was to occur.